中文

中文- +86-519-82337288

- engine@jsemei.com

中文

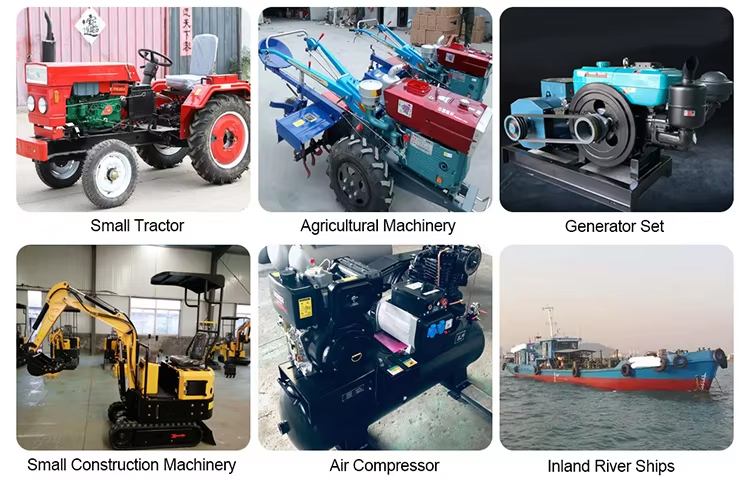

中文Single-cylinder diesel engine is widely used in agricultural machinery, small generator sets, inland ships and other fields due to its simple structure, low cost and convenient operation. It is a "little giant" that drives many equipment. To understand how it works, we need to start with its structure and then explore its working process in depth.

1.Structure of single-cylinder diesel engine

Single-cylinder diesel engine consists of multiple systems and components. Cylinder block, cylinder head and oil pan constitute the skeleton of diesel engine and provide support and installation position for other components. The moving parts are piston, connecting rod and crankshaft. The piston moves back and forth in the cylinder and transmits power to the crankshaft through the connecting rod, so that the crankshaft rotates. The valve mechanism includes intake valve, exhaust valve, camshaft, etc., which are responsible for controlling the intake and exhaust process. In addition, the fuel supply system, lubrication system, cooling system and starting system are also indispensable. The fuel supply system provides fuel for combustion, the lubrication system reduces component wear, the cooling system prevents the diesel engine from overheating, and the starting system allows the diesel engine to start smoothly.

2. Working process of a single-cylinder diesel engine

Single-cylinder diesel engine converts the chemical energy of the fuel into mechanical energy through four strokes: intake, compression, work, and exhaust, to achieve external work.

① Intake stroke:Driven by the crankshaft, the piston moves from the top dead center (the position where the piston is farthest from the center of the crankshaft) to the bottom dead center (the position where the piston is closest to the center of the crankshaft). At this time, the intake valve is open and the exhaust valve is closed. The cylinder volume gradually increases, the pressure in the cylinder decreases, and negative pressure is formed. Under the action of the pressure difference, air is sucked into the cylinder through the intake valve. Since single-cylinder diesel engines usually use natural aspiration, the intake resistance is small, which can ensure that sufficient air enters the cylinder. When the piston reaches the bottom dead center, the intake valve is closed and the intake stroke ends.

② Compression stroke:After the intake stroke ends, the piston moves from the bottom dead center to the top dead center, and the intake valve and exhaust valve are closed. The air in the cylinder is gradually compressed, the volume decreases, and the pressure and temperature continue to rise. The compression ratio of a single-cylinder diesel engine is relatively high, generally between 16 and 22, which makes the temperature of the air in the cylinder reach 500-700℃ at the end of compression, far exceeding the auto-ignition temperature of diesel. The highly compressed air creates good conditions for the subsequent combustion of diesel.

③ Power stroke:When the compression stroke is near the end, the fuel injector sprays high-pressure diesel into the cylinder in a mist form. The mist diesel and the high-temperature and high-pressure air quickly mix to form a combustible mixture and immediately self-ignite. The high-temperature and high-pressure gas generated by the combustion expands rapidly, pushing the piston from the top dead center to the bottom dead center, and driving the crankshaft to rotate through the connecting rod to perform external work. In this process, the internal energy of the gas is converted into the mechanical energy of the piston, providing power output for the diesel engine. This is the only stroke in the working cycle of a single-cylinder diesel engine that performs external work, and the quality of its work directly affects the performance of the diesel engine.

④ Exhaust stroke:After the power stroke, the piston moves from the bottom dead center to the top dead center, at which time the exhaust valve opens and the intake valve closes. The exhaust gas after combustion is pushed by the piston and discharged from the cylinder through the exhaust valve. When the piston reaches the top dead center, most of the exhaust gas is discharged, the exhaust valve is closed, and the exhaust stroke ends. Then, the diesel engine enters the next working cycle, repeats the above four strokes, and continuously outputs power.

3. Precautions in practical application

In practical application, in order to ensure the normal operation of the single-cylinder diesel engine, it needs to be maintained regularly. Ensure the cleanliness of the air filter, fuel filter, and oil filter to prevent impurities from entering the diesel engine and aggravating the wear of components.

Comments List